Carnegie Mellon Researchers Create Innovative Foldable Furniture Using Robotic Quilting & Origami-Inspired Design

Carnegie Mellon Researchers Create Innovative Foldable Furniture Using Robotic Quilting & Origami-Inspired DesignIf you’ve ever struggled with frequent moves or tight living quarters, this innovation could be perfect for you. At Carnegie Mellon University, researchers have engineered...

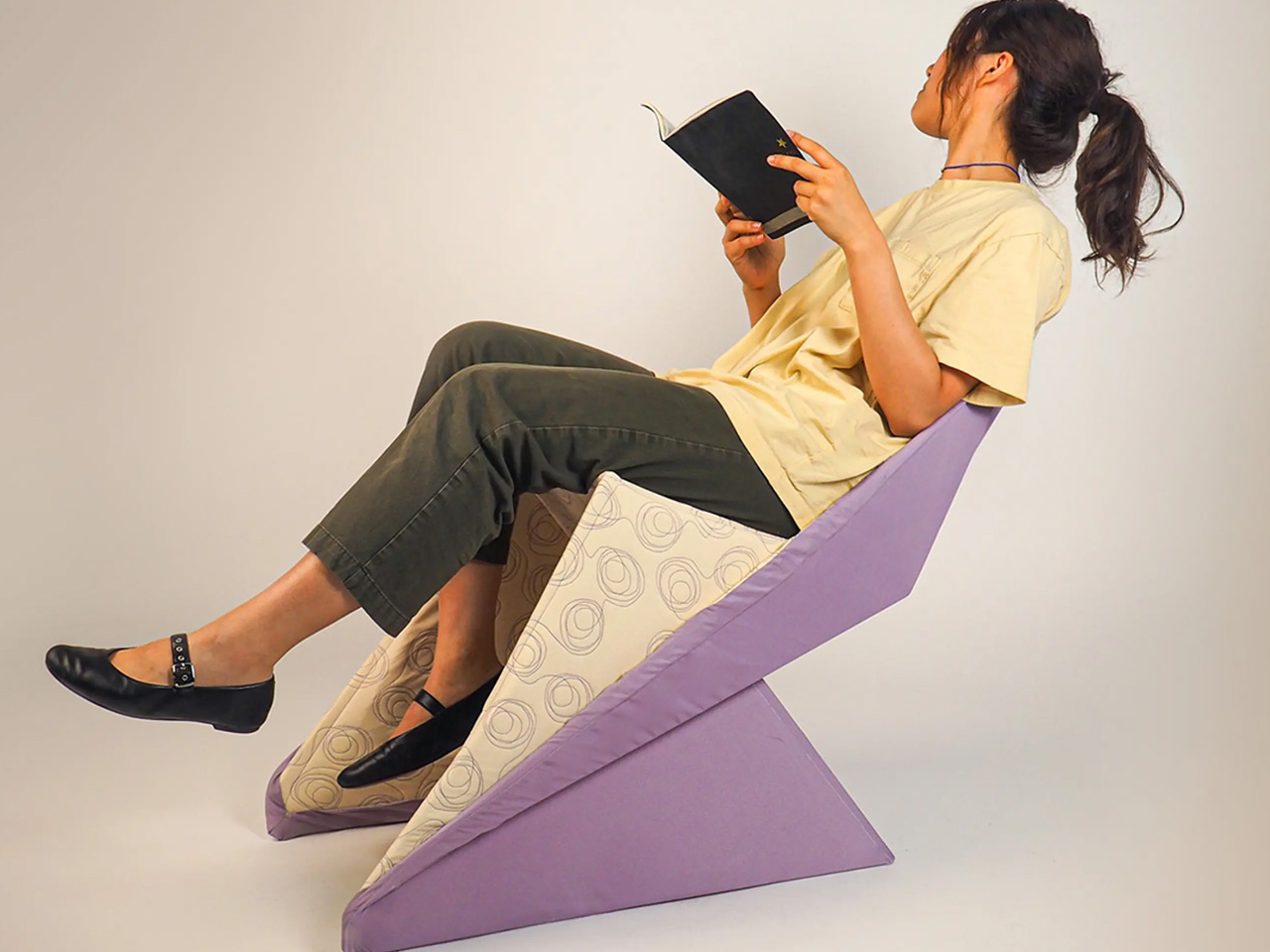

If you’ve ever struggled with frequent moves or tight living quarters, this innovation could be perfect for you. At Carnegie Mellon University, researchers have engineered a robotic quilting technique that transforms fabric-covered, lightweight panels into foldable home furnishings. Using this approach, the team has produced a range of items, such as a chair, a side table, a lamp, and even a backpack. Each piece combines layers of plywood and acrylic, all wrapped in different fabrics. The designs draw inspiration from origami, utilizing fabric-based hinges that simplify the assembly process and also add to the overall sturdiness of the furniture.

Designers: Sapna Tayal, Lea Albaugh, Mark Stehlik, James McCann, and Scott E. Hudson

The researchers explain that their project demonstrates how existing CNC quilting machines can be repurposed to create entirely new functional objects, eliminating the need for extra components like metal hinges or the manual labor typically required for assembly. This approach could pave the way for a fresh category of furniture, encouraging designers to experiment with innovative geometric forms and new product ideas.

Here’s how the process works: it utilizes a CNC long-arm quilting machine—a computer-guided sewing device capable of handling large fabric sections and stitching together multiple material layers, much like those used in quilts. The team employed a particularly large model, with a 32-inch (0.81 m) reach and a 13-foot (4 m) length, allowing them to fabricate various designs. This machine can follow precise vector paths imported through its specialized software, offering significant creative flexibility.

Each piece is constructed by sandwiching rigid panels, such as plywood or acrylic, between layers of fabric. During the sewing process, these layers are stitched together to form soft, flexible hinges between the solid inserts, enabling the flat structure to unfold into three-dimensional furniture. This adaptable technique makes it easy to customize materials based on the specific needs of each item.

For example, the lamp incorporates sheer fabric to let light shine through, while the lounge chair relies on thicker plywood for added support and durability. To further enhance functionality and stability, components like tendon cords, magnets, and hook-and-loop fasteners are sewn in, ensuring smooth deployment and a secure final shape.

The designs featured in this project each incorporate unique functional details. For instance, the side table uses a tendon cord threaded through its struts to pull them inward, forming the table’s shape and providing stability. The backpack, inspired by packaging, also employs a tendon cord system, which serves as straps and aids its transformation.

Hook-and-loop fasteners keep the flaps securely closed. The table lamp is adapted from a 3D-printable Lang’s Elliptic Infinity lamp, using acrylic panels for a lightweight look and integrated LEDs for illumination. The lounge chair, built to support an adult, uses thicker plywood inserts and embedded neodymium magnets to align panels. Developing these pieces required careful planning, precise material placement, and experimenting with various fabrics.

The post Carnegie Mellon Researchers Create Innovative Foldable Furniture Using Robotic Quilting & Origami-Inspired Design first appeared on Yanko Design.